3D Modelling & Printing

Modified:

3D Modelling

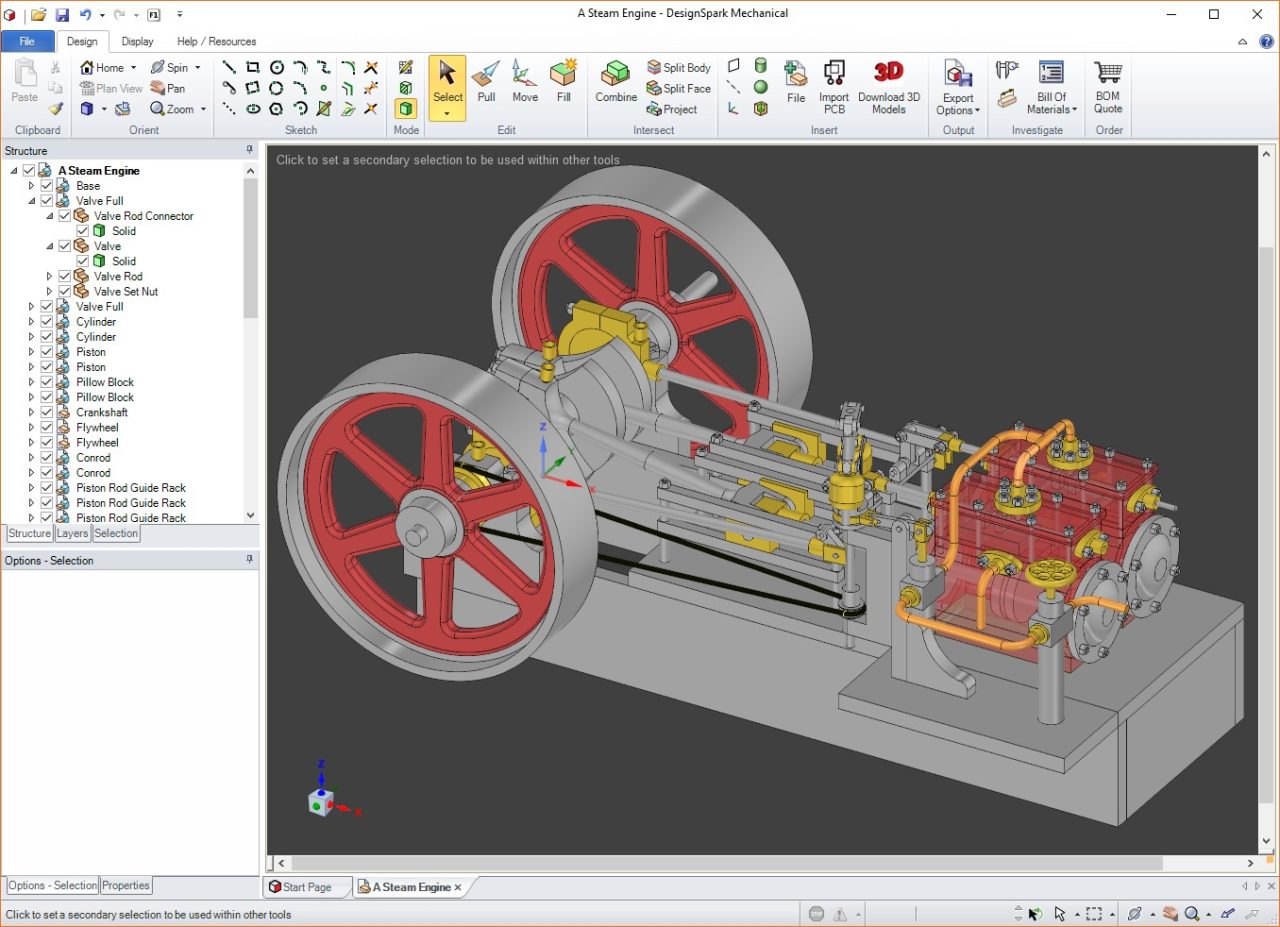

3D Modelling is now easier than ever, and 3D printers have become more affordable for the home user. My favourite software tool for 3D modelling currently is DesignSpark Mechanical. It has a free tier, with the other tiers being very affordable. There are of course limitations in the free tier, but the only limitations that affect me are the locked down import / export formats and the mirror tool.

I have been using DesignSpark mechanical for years, since it was released and am very familiar with it, which is the main reason I have not tried any other tools yet.

Others that are free or have free tiers are:

- Autodesk Fusion 360 – Excellent, can animate 3D models, but free version comes with limitations

- Solid Edge Community Edition – Excellent, but comes with limitations

- OnShape – Excellent, online but no private documents

- FreeCAD – Fully free but steep learning curve

- Shapr3D – Nice modern interface, but free version is too crippled

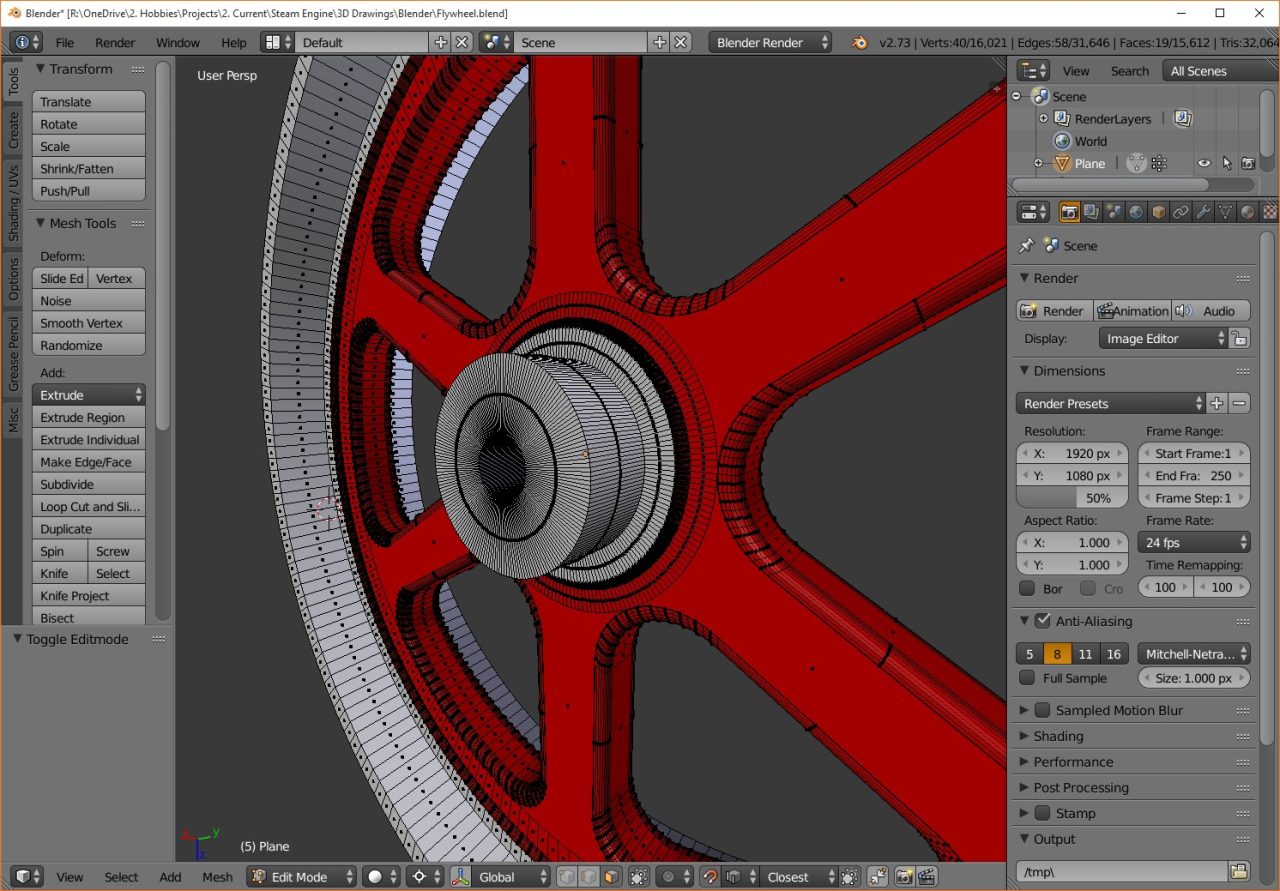

- Blender – Exceptionally powerful for mesh-based modelling, but not suited to technical modelling

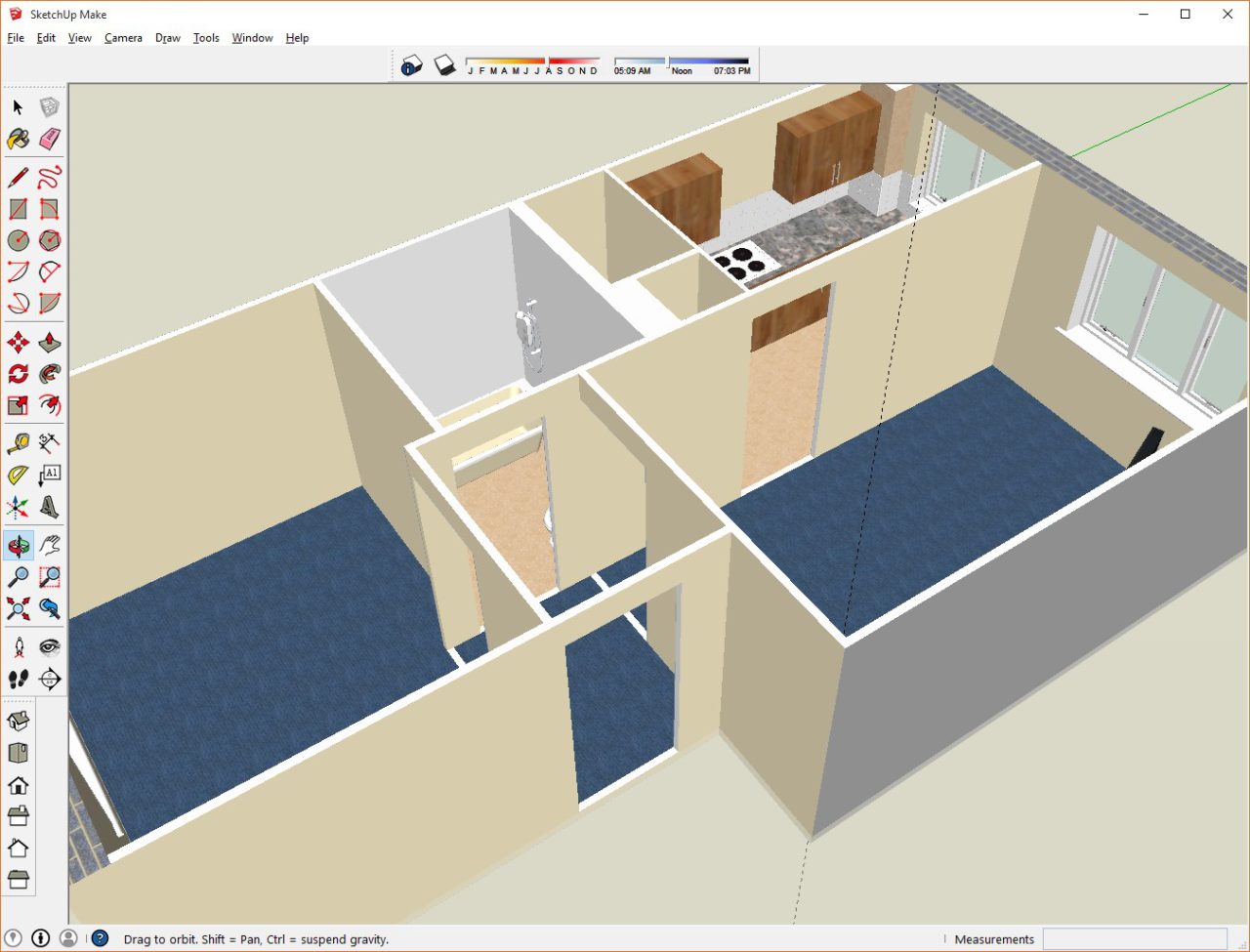

- Sketchup – Not suited for technical modelling or precision 3D printing

3D Viewer Instructions

Mouse Wheel OR Shift + Left Button to Zoom | Left Button to Rotate | Right Button OR Shift + Left Button to Pan

In addition to creating objects for 3D printing, I find 3D modelling invaluable for designing things I want to build. This is especially useful for complex objects, such as an electric cart, steam engine, and for furniture and construction, such as a book case, garage conversion, workshop. If I need to visualise how different components of a product would fit together spatially, I design a 3D model.

I started 3D modelling with a product called SketchUp, which was owned by Google at the time, and has since been acquired by Trimble. There is still a free version called SketchUp Make. SketchUp has a short learning curve and is very easy to use to create detailed 3D models. I created a model of the flat I was living in at the time.

However, SketchUp did not appeal to me for engineering models, and I looked for some more advanced software.

I found Blender, which is free open source software. It is extremely powerful and can do mesh modelling, sculpting, animation, simulation and has a whole lot of other features. It also has one of the best user interfaces I have ever had the pleasure of working with.

Blender is very powerful and lets you manipulate individual (or grouped) vertices, edges and faces. In fact you work at that level. It has some tools that allow you to manipulate these in groups, but you are still working at a very low level. Because of this, Blender has a long learning curve. I initially chose Blender to do all my 3D modelling, so I watched and practised most of the free tutorials at BlendTuts Home Page, or BlendTuts on YouTube. These are really good tutorials!

I started using Blender for my Stationary Steam Engine project, and created the flywheel and a few other parts.

Then I discovered DesignSpark Mechanical! It was completely free at the time, and is provided by RS Components. DS Mechanical is easy to learn, but powerful, and more suited to engineering models. DS Mechanical is a direct modelling application, so you are working with and manipulating solids, and creating models (especially for engineering purposes) is much faster than with Blender, and the software has a shorter learning curve. I was really impressed at how easy it is to create complex shapes to exact dimensions.

Here is an introductory video:

3D Printing

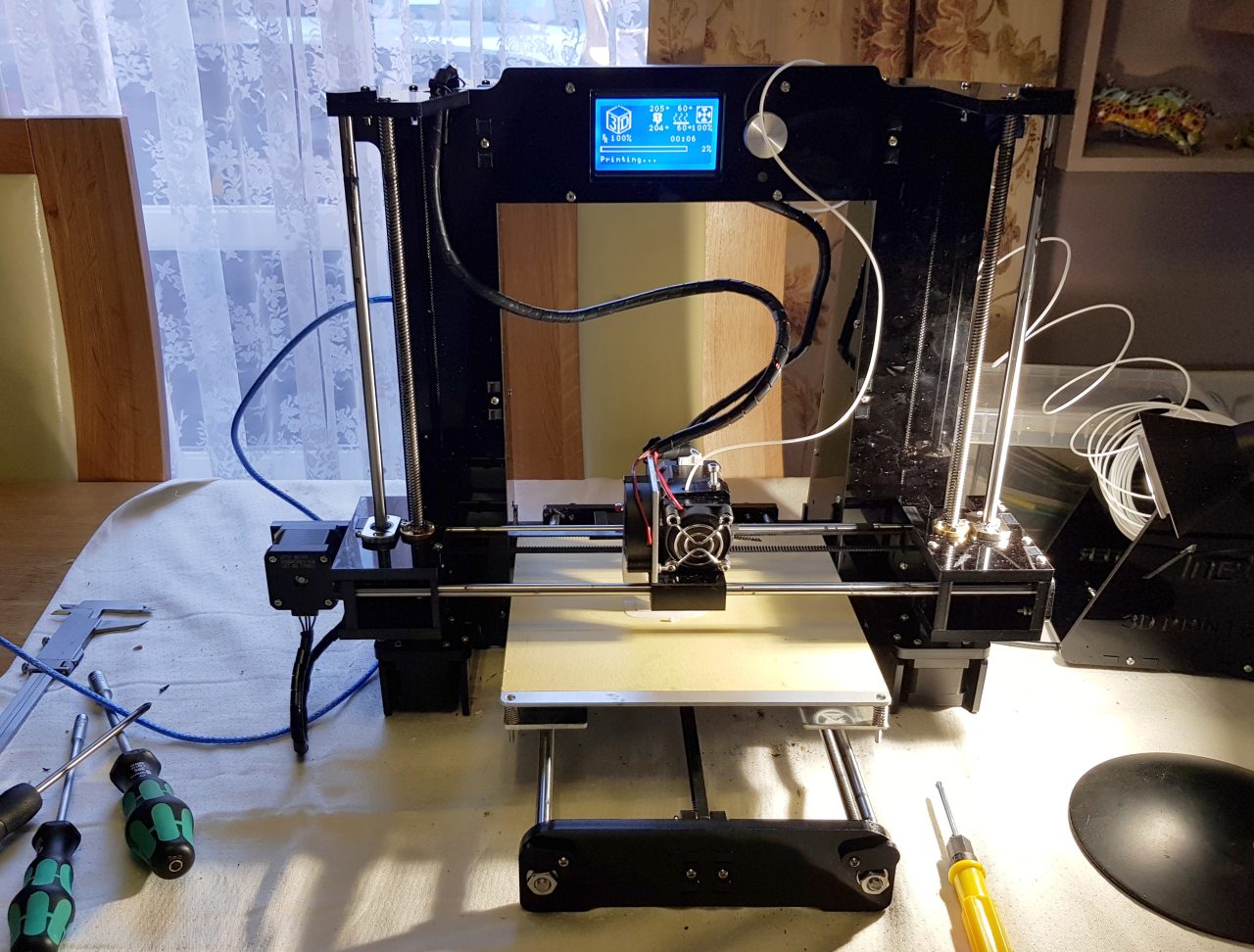

I purchased an Anet A6 printer in 2017 to produce parts for my own projects, but after discovering Thingiverse, I couldn’t resist printing other types of items as well! See the T-Rex I printed, as well as the Egyptian chess set. I also printed a number of smaller gadgets: the heart gears, a mobius bangle, nautilus gears and a whistle!

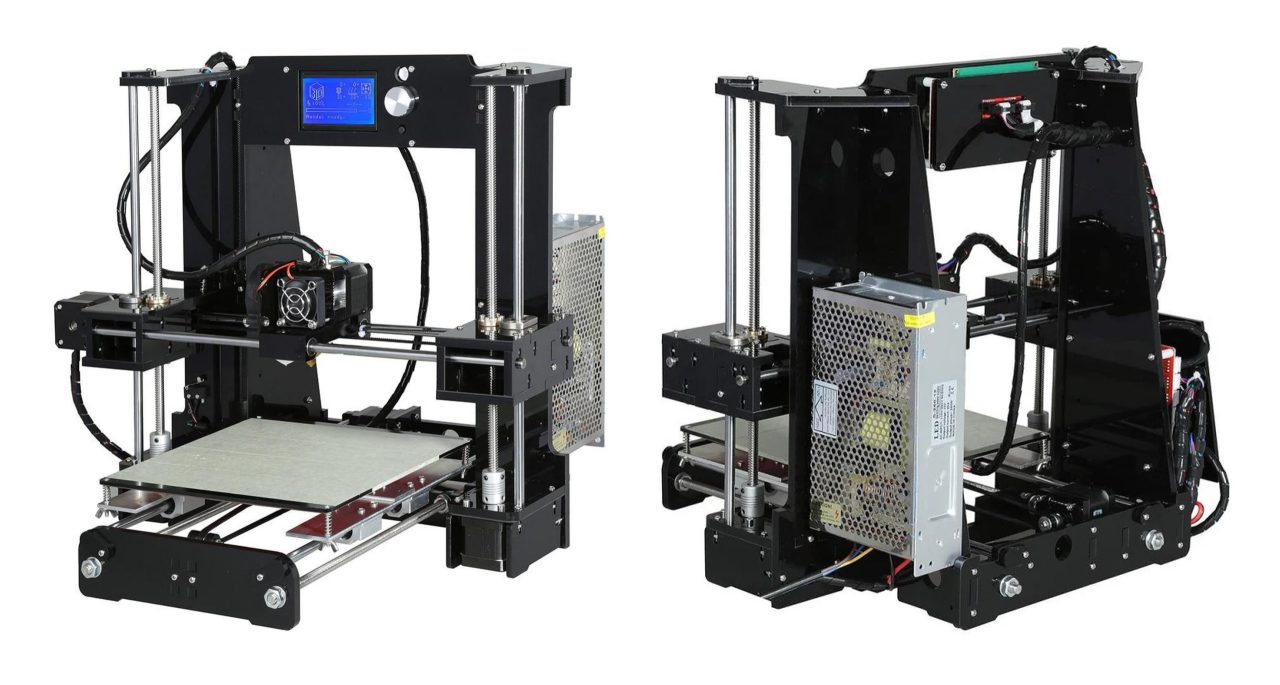

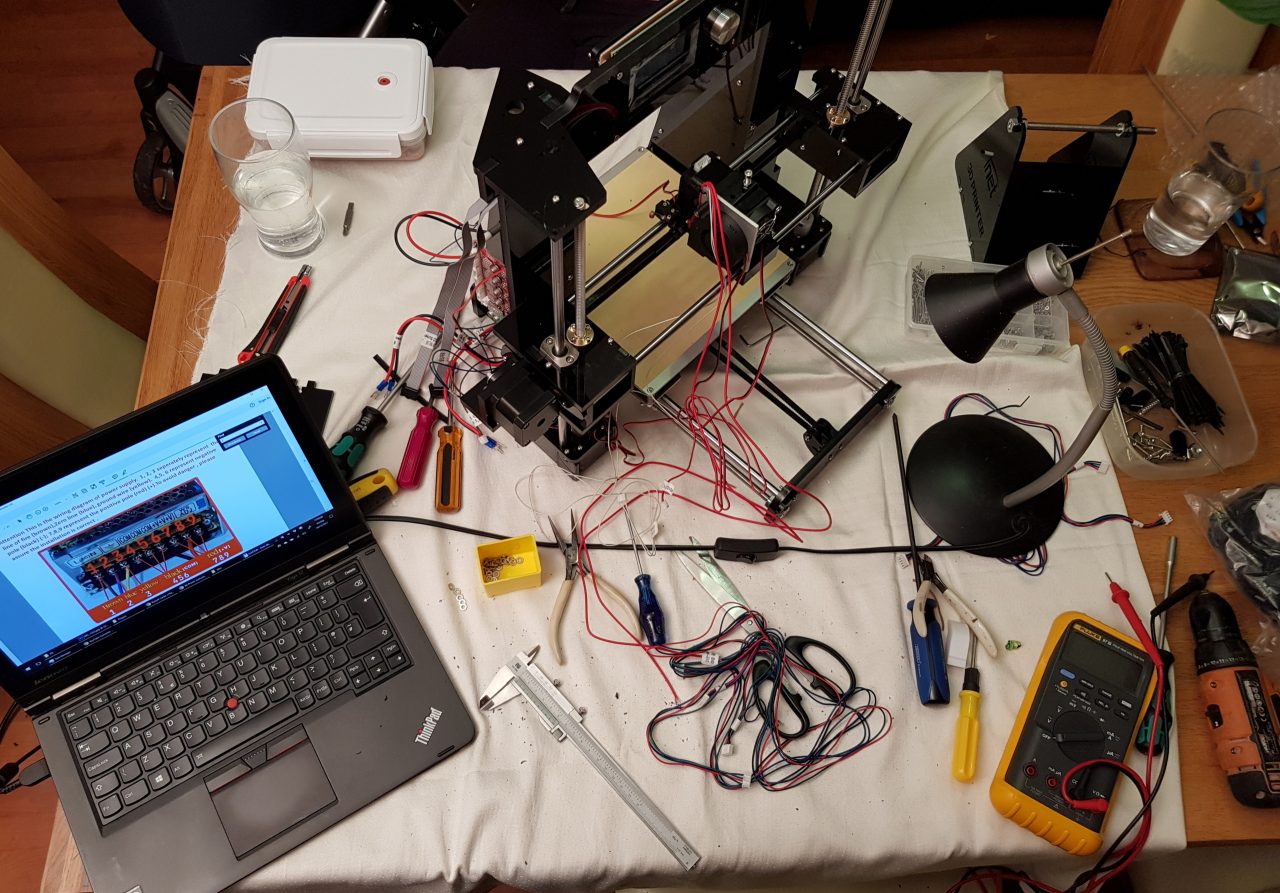

The Anet A6 is a self-assembly 3D printer designed primarily for PLA, with the frame made from laser-cut acrylic and the kit including all mechanical components, pre-wired harnesses, a control board, and a power supply. Assembly took several hours.

While the model was known for safety issues (including fire risks), I’ve personally had no problems. It is a relatively simple printer, but works well if you assemble it correctly and ensure your connections are all secure. The printer has since been discontinued, and newer models offer significantly improved capabilities and safety features.

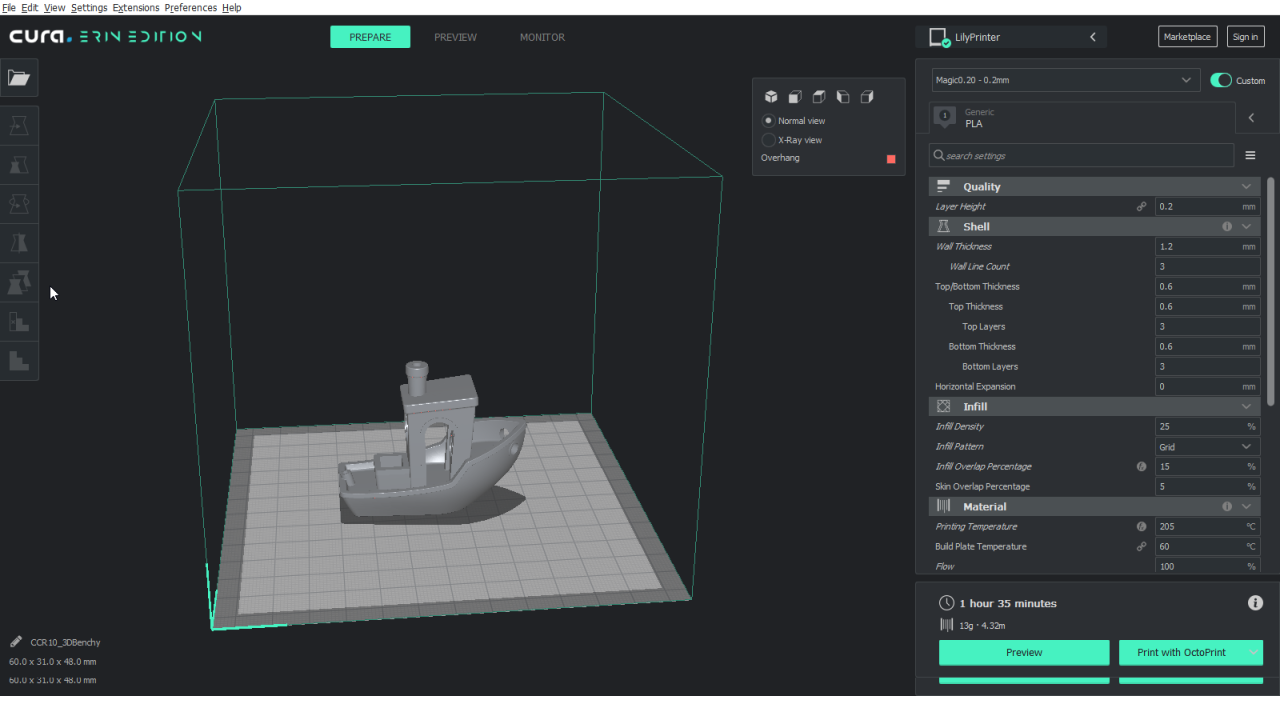

I use Ultimaker Cura on my PC to manage the printing, which works well for me, but may consider Octoprint in future.